|

Get a professional quotation for your steel structure within 2 hours,welcome to inquiry. E-mail:[email protected] Mobile/WhatsApp/Wechat:0086-13588124297 Technical Details Download:here about packing:here |

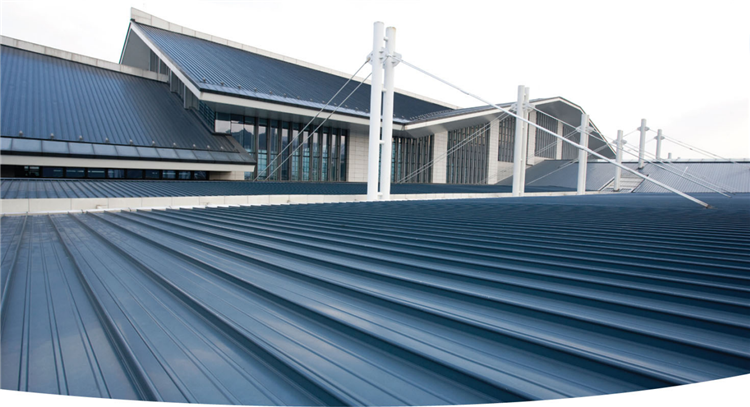

Desen Roofing System Advantages

•No fasteners penetration ensures superior weather tightness performance

•Advanced concealed clip system provides excellent uplift resistance

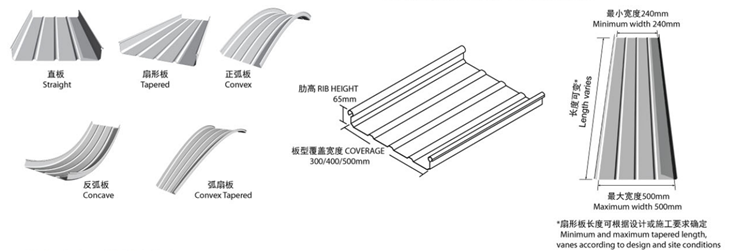

•Available in tapered and curved sheets to fulfill the most challenging design criteria

•Can be roll-formed on site to avoid end overlapping

•Available in a range of cover widths in ferrous and non ferrous material

•Original clips design minimize the need for roofing thermal expansion joints

•Specially engineered thermal pad of the clip can reduce thermal bridging effects

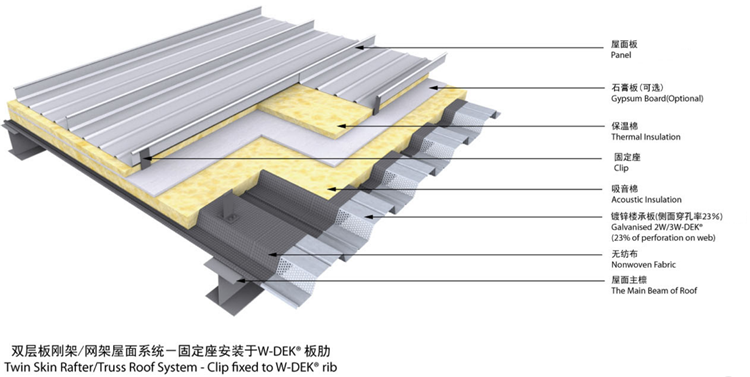

SYSTEM FEATURES:

Desen Roofing System is a structural architectural roofing panel that is mechanically field seamed for water tightness and resistance to wind uplift

Concealed fix thus providing a continuous weather tight roof ;

Available in tapered and curved sheets with a minimum radius of 3m to fulfill the most challenging design criteria ;

Available in a range of cover widths in ferrous and non ferrous material ;

The minimum roof pitch is 1° ;

The original clip has an inbuilt thermal bridge and allows movement resulting from thermal expansion ;

Various roof designs achieve heat insulation and acoustic performance;

Can be roll-formed on site to achieve extreme long length according to project requirement

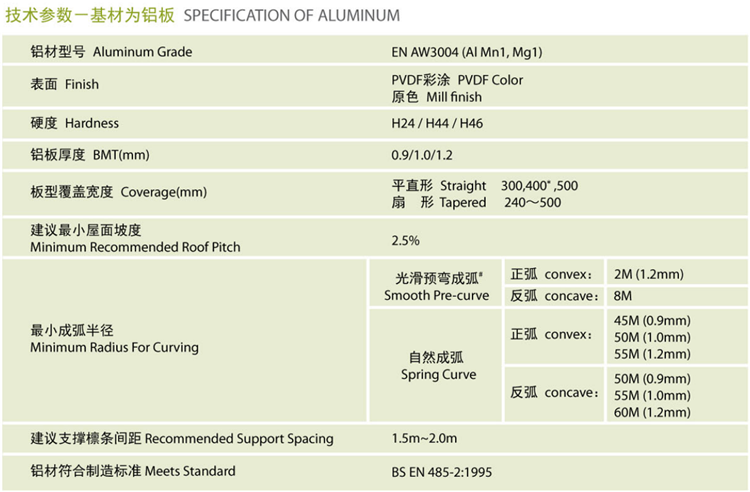

SPECIFICATION

SPECIFICATION:

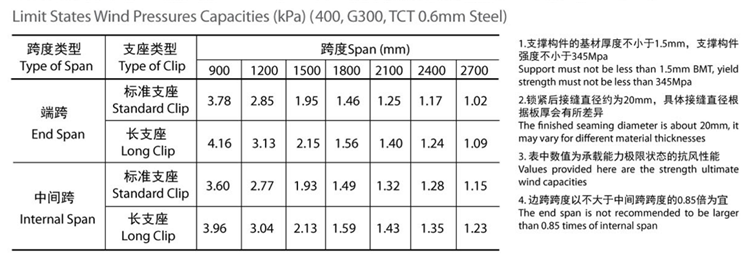

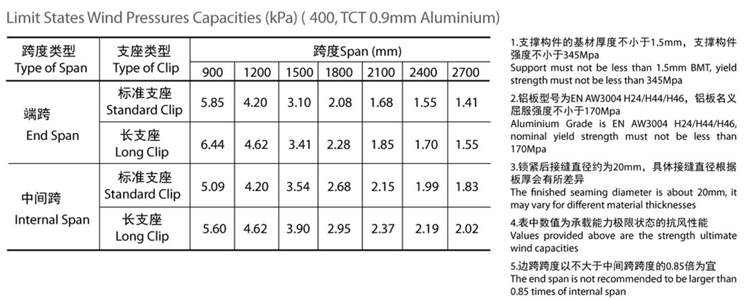

Limit States Wind Pressures Capacities (kPa):

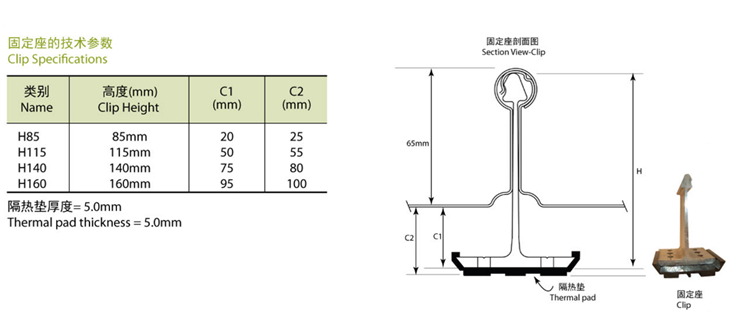

Clip System:

•Desen Clips are extruded from structural grade aluminium. The shape of the dip has been carefully designedto maximize strength, in both upward (wind uplift) and downward (snow, wind, dead load) conditions.

•The head of the dip accurately matches the desen sheeting, to ensure the sheets slide freely during thermal movement.

•Desen clip is made from:Aluminium Alloy 6005A to AS/NZS 1866 or Aluminium Alloy 6063-T5

H = height of clip without thermal pad

Cl = Cavity without thermal pad

(between Desen panel and bottom edge of dip)

C2 = Cavity with thermal pad

(between Desen panel and bottom edge of thermal pad)

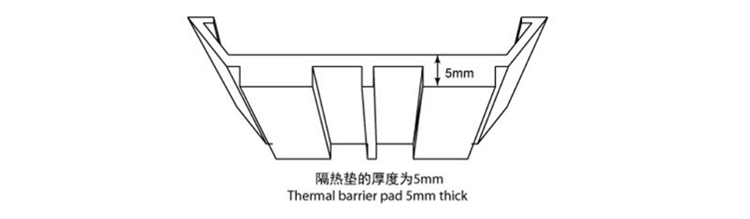

Thermal Pad

Specially engineered thermal pad slides neatly onto the base of the dip reducing thermal bridging effects.

Installation

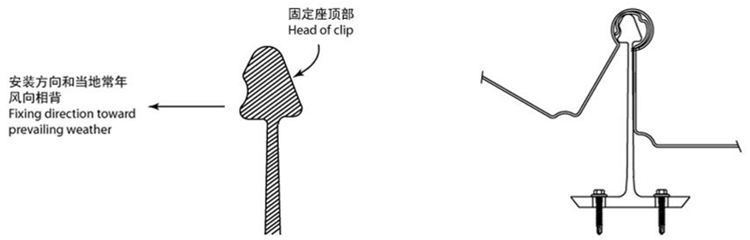

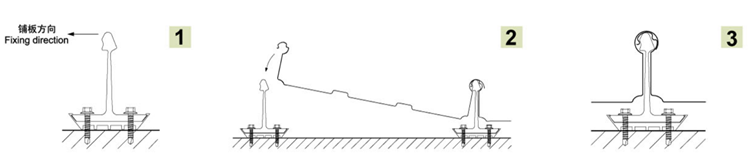

Orientation of Clips

Where possible, the direction of installation should be toward the prevailing weather conditions. This ensures the overlap locates on the leeward side.

The orientation of the Desen clip shall be in accordance with adjacent diagram i.e. the notch side of head faces in the direction of laying.

Correct orientation of the dip ensures the sheets will expand and contract smoothly during temperature changes.

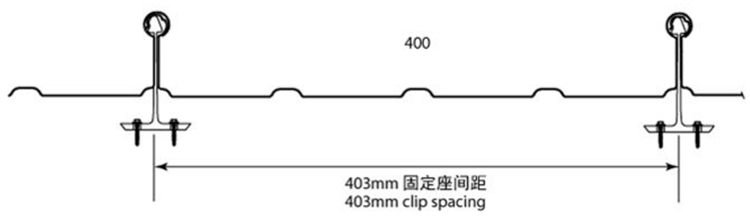

Lateral Spacing of Clips

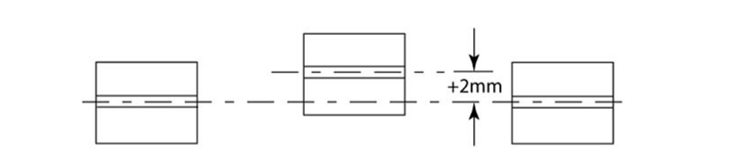

Lateral spacing of clips depends upon the Desen profile being used. For best results, clips should be spaced with a cover

width plus 3.0mm. For example, Desen 400 the lateral clip spacing is ideal at 403mm. For curved roofs, increase the spacing to 3-5mm depending on the radius of the Desen panel.

Longitudinal Spacing of Clips

Longitudinal spacing of clips (or Cladding Span) is determined by considering wind uplift, downward loads (wind and snow) and walk-on capacity.

The highest of the three will determine allowable dip spacing.

Careful consideration should be given to areas of a structure which experience high localized loads (e.g. ridge and eaves). It is common practice to reduce spacing of dips in these areas. To ensure adequate thermal movement of the system is maintained, longitudinal spacing of clips must be carefully aligned during installation.

Installation Process:

Step one: Fixing clips. Desen roofing is anchored onto the purlins with heat insulated concealed dips. Pay attention to the correct direction;

Step two: Fixing male and female ribs on the dips: place the female rib overlapping the male rib of the previous sheet;

Step three: Lock up the ribs by machine on site.

Seamer:

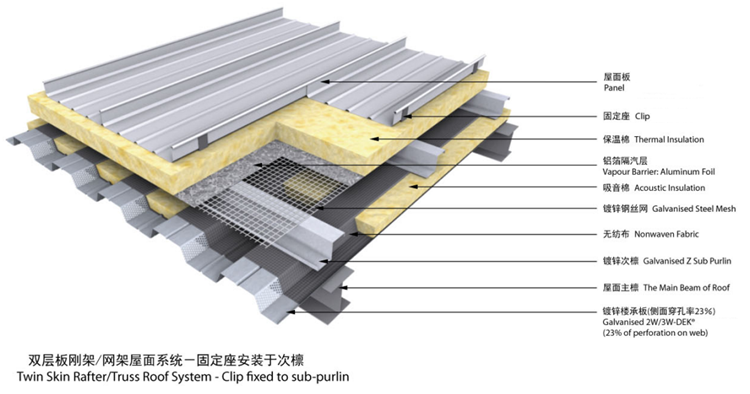

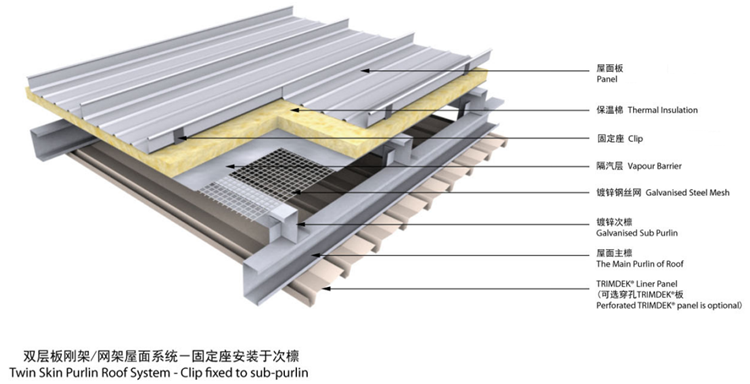

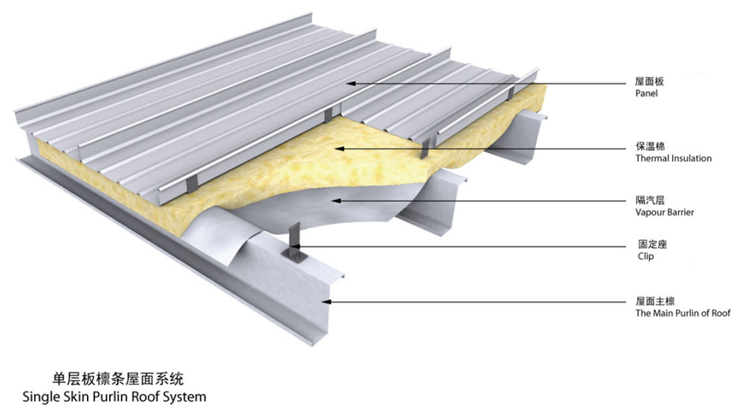

Typical Systems

FAQ of this One-stop service for steel structure

1.What’s the design code are you adopt?

Answer: Usually we adopt GB 50017-2003/JGJ7-2010 code, however European standard also practice. We offer world-class steel structure and space frame design which have cost effective solution for both steel structure and foundation construction too.

2.What’s the design software are you using?

Answer:MSTCAD, SAP2000, Midas,3D3S,PKPM

3.What’s the drawing software?

Answer: AutoCAD, Tekla etc

4.Are you manufacturer?

Answer: Yes, we are steel structure space frame manufacturer and solution provider as well, and we have world class steel structure and space frame (coal shed) design experience, and follow ISO standard mainly, however ASTM also possible for us.

5.What kind of steel you are using?

Answer: Usually we use middle steel Q235B and high tensile steel Q355B for steel structure and space frame.

6.Warranty years and life time of steel structure and space frame?

Answer: The warranty year is 2 years and lifetime of steel structure and space frame is 50 years.

7.What’s the minimum order quantity would be?

Answer: Minimum order quantity is 1xfull container.

8.What’s the production lead time?

Answer: Usually it will take 1 month for the manufacturing after the PO and down payment.

9.Are you close to the sea port?

Answer: Yes, we are near to the one of the biggest port in the world and it’s the one of our advantage to export the cargos worldwide.

10.How to control the quality?

Answer: We are ISO 9001 qualified since 2009 and treat quality first as our strategy, we do everything which include checking the manufacturing cards, do prototype assembly and counting the each steel members carefully before the shipment and so on, so that we can avoid possible mistake in Client’s side.

R&D Department

Technology center of DESEN was founded in 2010. At present, there are over 10 R & D design and technical engineers, and among them here are 8 national registered construction and structure engineers and 2 senior engineers, forming an experienced and skilled professional team and laying a solid foundation to DESEN's design and technology products.

Contact: Abner

Phone: 0086-13588124297

Tel: 0086-571-56683606

Email: [email protected]

Add: Room 1115, Building 24, Yaoshunjiangdongjinzuo, Yipeng Street, Qiantang New Area, Hangzhou, Zhejiang

We chat