1. Hang members onto the display area, check whether the members correction ( next to bend / twisted / camber, and so on ) is qualified. After confirmation of qualification, underline the center line and milling lines of every surface, and type the punch marks.

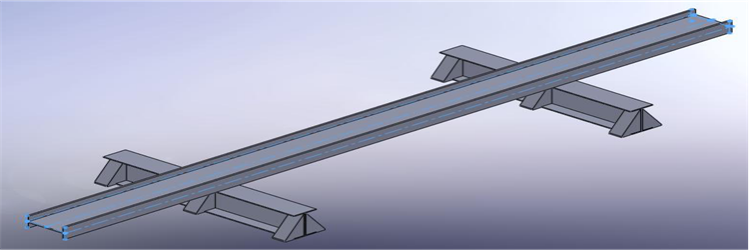

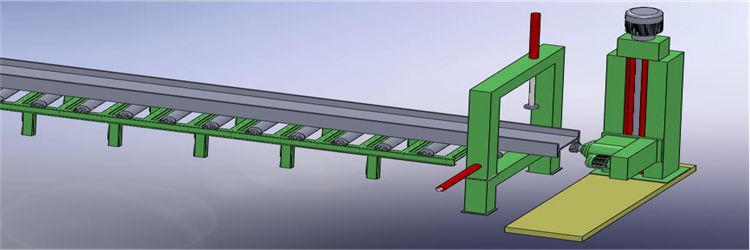

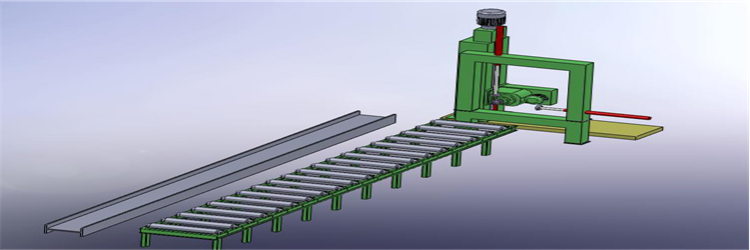

2.Place the member on processing platform and adjust; ensure that the member and the two props in the front and back are pressed tightly.

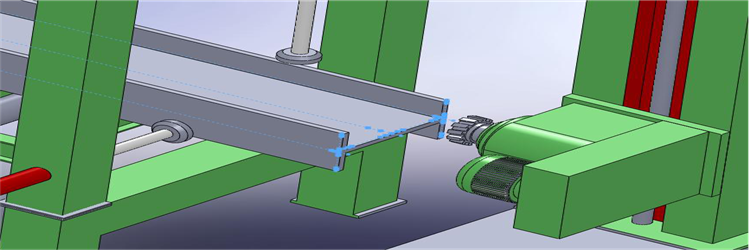

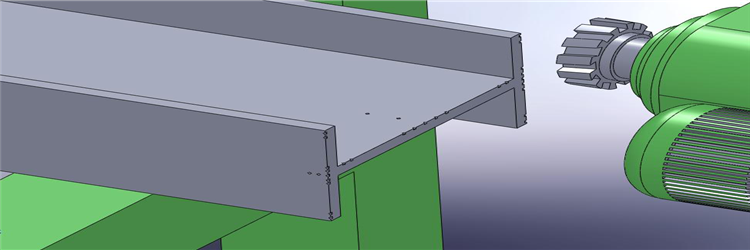

3.After finishing the adjustment, start fastening top device to press the members tightly, and then make adjustments to the cutter, making heads parallel to mill line.

4.Adjust the parameter and start milling; (parameters include the feed volume, milling speed, speed etc, and note that o the last milling amount should be smaller )

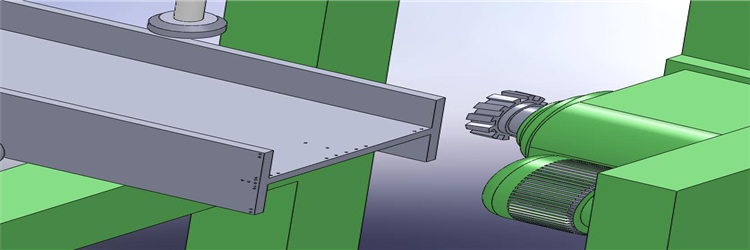

5.Milling will be completed until half a sample punch mark position is made left, and then start self test of the member; deviation permitted is ±2mm, and that of milling flat plane

6.When milling self test are qualified,hang the members out of milling platform.dimension is 0.3mm, and that of the verticality of the axis of milling flat is l/1500.

Contact: Abner

Phone: 0086-13588124297

Tel: 0086-571-56683606

Email: [email protected]

Add: Room 1115, Building 24, Yaoshunjiangdongjinzuo, Yipeng Street, Qiantang New Area, Hangzhou, Zhejiang

We chat